Inspections built for follow-up, not filing cabinets

Run inspections digitally to keep everything clean, simple, and trackable, without changing how your team actually works.

Why digital inspections matter

Most organizations already do inspections. The problem isn’t the inspections, it’s what happens to them after.

- Paper forms get filed.

- PDFs get saved to random folders.

- Books get handed to safety or operations.

Over time, everything becomes hard to find, hard to review, and nearly impossible to track.

A digital inspection system keeps everything organized automatically. The moment an inspection is completed, it’s logged, stored, searchable, and available to the right people, without extra admin work.

That means:

- less time filing

- less time chasing forms

- more visibility into what’s actually happening

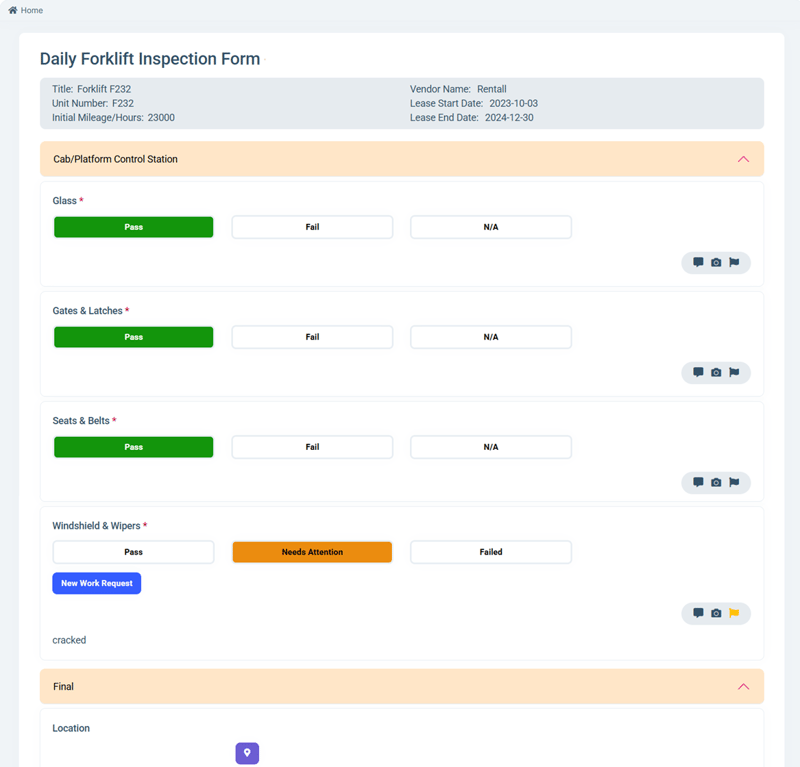

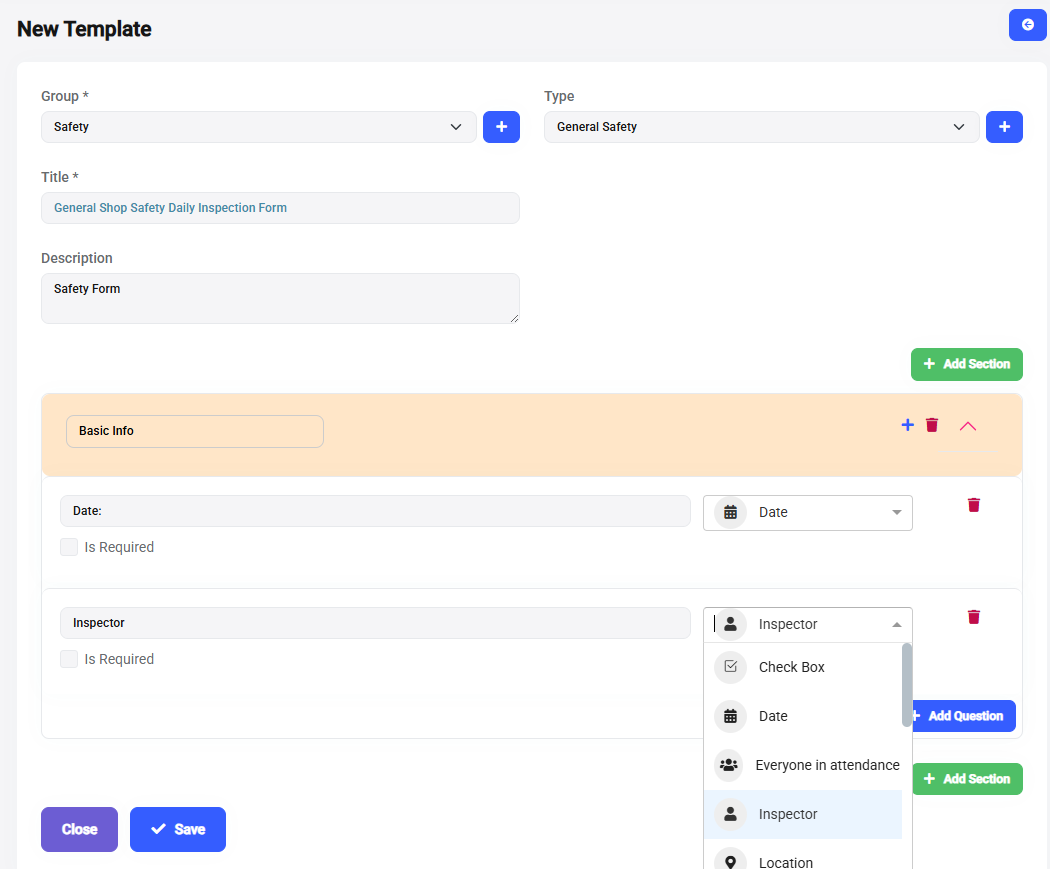

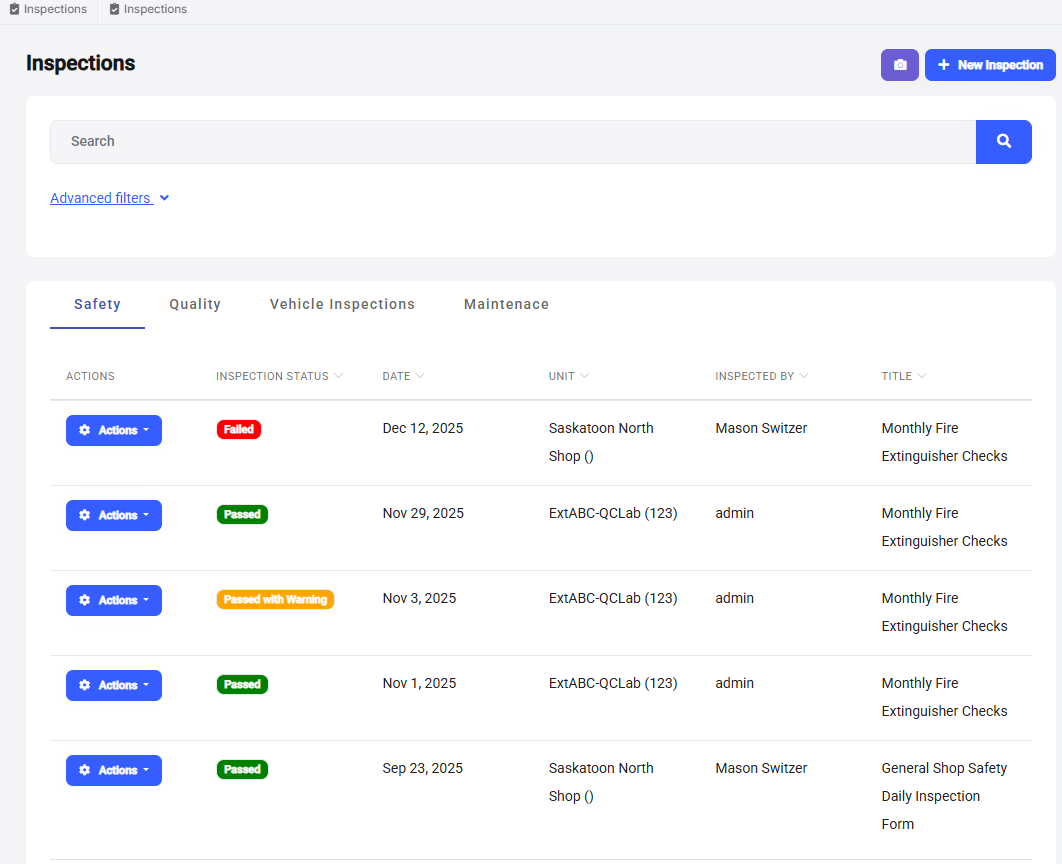

Simple, customizable forms

Build inspection forms that match exactly what you need for safety, vehicles, quality, production, or any internal process.

Forms are easy to create, easy to update, and work for:

- Daily checks

- Compliance inspections

- Internal audits

- Equipment PM

QR-based access

Attach a QR code to equipment, or work areas.

Scan it on any phone or tablet to open the correct inspection instantly.

- No searching.

- No guessing

- No wrong forms

Perfect for teams that need fast access

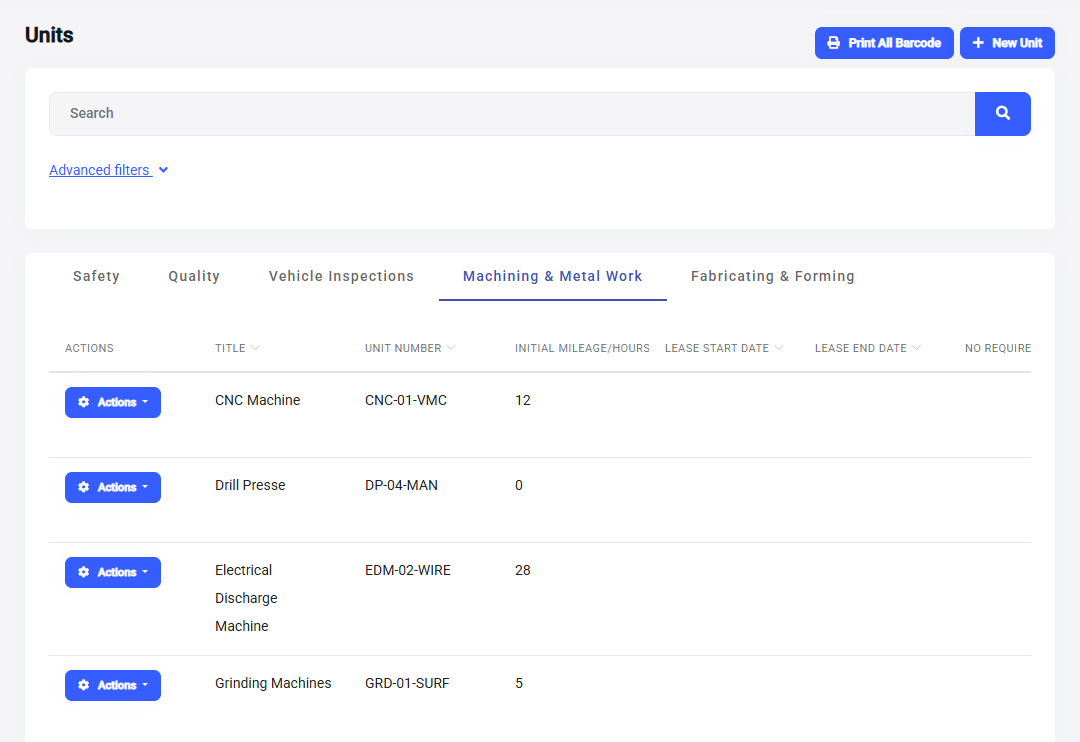

Real asset tracking

Run inspections against actual vehicles, machines, tools, or locations.

Every asset keeps its own history, so you can see:

- past inspections

- recurring issues

- trends over time

No more second guessing or digging through files.

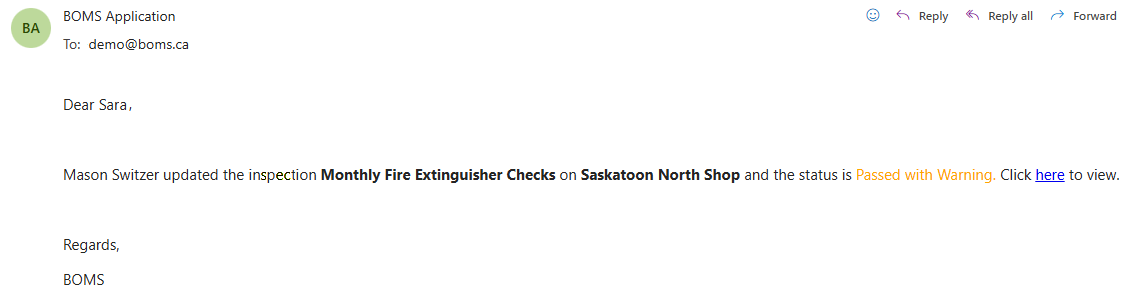

Stay informed without chasing people

Automatic logging

All inspections are saved instantly.

Smart notifications

Get alerted when inspections are completed or failed.

Mobile & offline

Works even without internet access.

Clear history, real trends

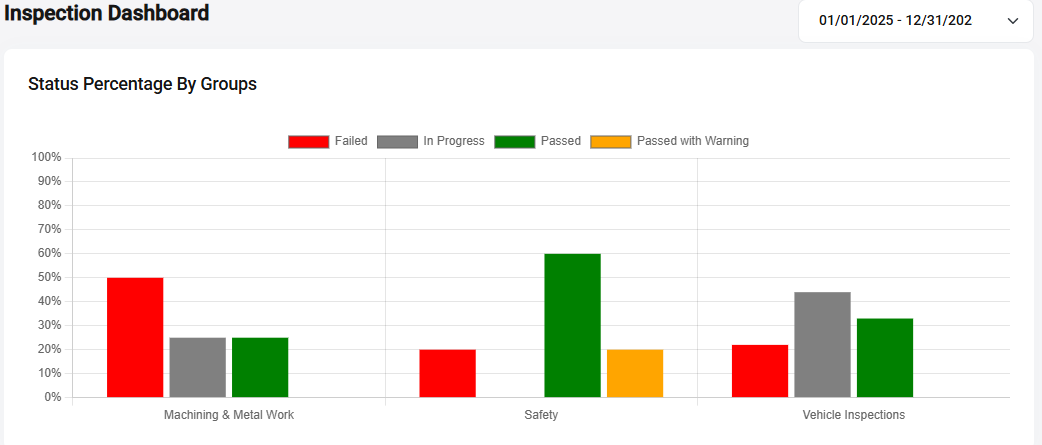

With everything in one system, you get a live dashboard showing what’s happening across:

- vehicles

- equipment

- safety checks

- operational inspections

This makes audits easier, reviews faster, and decision-making far more reliable.

Instead of asking:

“Did that inspection get done?”

You can simply see it.

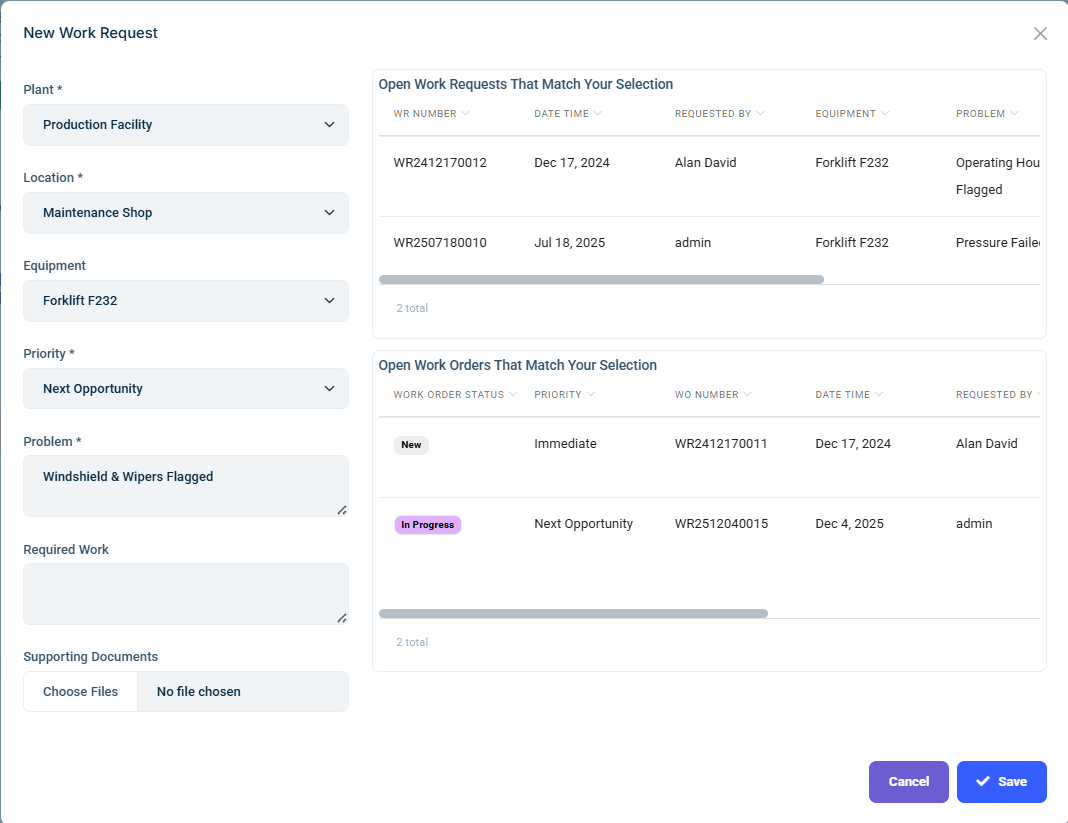

When inspections connect to action

Inspections work perfectly on their own.

But when paired with maintenance, something powerful happens.

If a vehicle or machine fails an inspection, the system can prompt a maintenance request immediately.

No middlemen.

No emails.

No sticky notes.

Just a direct, traceable link between:

what needs fixing → who is responsible

The real outcome

Inspections become easier to complete.

Data stays clean and organized.

Teams stay informed.

Issues stay visible.

And nothing gets lost.

Inspection management, answered

Can we use inspections without the maintenance module?

Yes. Inspections work completely on their own. You can build forms, assign them to equipment or vehicles, track results, and run reports without using any other part of the platform.

The maintenance connection is optional, it just adds an extra layer of automation when you’re ready for it.

What types of inspections can we run?

Anything you currently do on paper or in PDFs, including:

- safety inspections

- vehicle inspections

- equipment checks

- quality inspections

- production walkarounds

- internal audits

If it can be turned into a form, it can be built in BOMS.

How customizable are the forms?

Very. You can add different question types like:

- checkboxes

- pass/fail

- photos

- signatures

- numeric fields

- comments

- attachments

- and more!

This lets you match your real-world inspection process instead of forcing your team into rigid templates.

How do QR codes work?

Each piece of equipment, vehicle, or location can have its own QR code.

When someone scans it, they’re taken directly to the correct inspection forms for that asset, no searching or guessing required.

This makes inspections faster and reduces user error

What happens after an inspection is completed?

Once submitted, the inspection is:

- logged automatically

- visible in dashboards

- searchable for audits

- stored in the asset’s history

If something fails, you can trigger notifications or maintenance requests depending on how your system is set up.

Does it work on mobile?

Yes. BOMS has a dedicated mobile app for iOS and Android.

Users can complete inspections directly in the app, including scanning QR codes, attaching photos, and submitting forms on the spot.

The app also works offline, so inspections can still be completed in areas with limited or no connectivity. Data syncs automatically once the device reconnects

Is this built for compliance and audits?

Yes. Every inspection has:

- a timestamp

- a user

- a digital record

- full history

This makes audits faster and far less painful compared to paper systems.